Variable Capacitance MEMS Accelerometers

Variable capacitance MEMS (VC MEMS) accelerometers are DC-response sensors for measuring low frequency vibration, motion (constant acceleration) and tilt. Micro-Electro-Mechanical Systems (MEMS) technology is the backbone of VC accelerometers. PCB & Endevco variable capacitance accelerometers incorporate MEMS technology to provide accurate measurements in lightweight packaging. We offer both single axis and triaxial options for a variety of industries and applications.

PCB 3711F, 3713F, 3741F & 3743G Series

PCB 3711F, 3713F, 3741F & 3743G Series High Performance, Low Frequency Measurement

Learn More Endevco 7290G & 7290GM5

Endevco 7290G & 7290GM5 Fastest Shock Recovery for A&D Applications

Learn More Endevco 770A – 770F, 771, & 773

Endevco 770A – 770F, 771, & 773 General Purpose VC MEMS

Learn More Overview of Variable Capacitance Accelerometers

A fundamental understanding of variable capacitance (VC) accelerometers is essential for grasping the advanced technology behind these sensors.

Understanding Variable Capacitance and Accelerometers

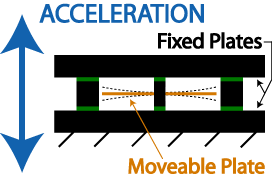

Traditional piezoelectric accelerometers measure changes of charge, but variable capacitance accelerometers use the properties of an opposed plate capacitor for which the distance between the plates varies proportionally to applied acceleration thus altering capacitance. This variable is used in a circuit to ultimately deliver a voltage signal that is proportional to acceleration. Capacitive accelerometers are capable of measuring constant as well as slow transient and periodic acceleration.

Features like frequency response, sensitivity, and damping make these accelerometers perform efficiently for low frequency measurement.

Measurement of Acceleration Using Variable Capacitance

Here's how it works: The sensor detects changes in capacitance caused by movement or motion. When your device experiences acceleration, the mass inside the accelerometer moves. This movement alters the capacitance between internal plates. Sensors then convert these minute changes into an electrical signal that reflects the acceleration.

High sensitivity to small capacitance variations is vital for precise measurements. Variable capacitance accelerometers excel in this area, offering robust performance even when detecting minuscule changes. Measurement ranges can vary widely, depending on the physical parameters of the design and application needs.

Micro-Electro-Mechanical Systems (MEMS) Technology

MEMS fabrication enables the creation of extremely small, durable, and highly sensitive sensors that can integrate seamlessly into various devices.

VC MEMS accelerometers leverage microfabrication techniques, allowing the production of sensors on a microscopic scale. This miniaturization enhances the sensitivity and performance of accelerometers, making them ideal for applications requiring compact and lightweight sensors. During the manufacturing process, gas damping is added to improve the robustness and reliability of these accelerometers, ensuring consistent performance even in demanding environments.

For more information see our Introduction to MEMS Accelerometers.

Advantages of Variable Capacitance Accelerometers

Every technology has its strengths and weaknesses. Understanding the advantages and limitations helps you make informed decisions about deploying VC MEMS in your test applications.

Advantages of Variable Capacitance Accelerometers

VC accelerometers are generally available with much higher sensitivities than many accelerometers. VC accelerometers are ideally suited to measure low-frequency, low-level accelerations (of an aircraft wing, automobile motion or wind-induced sway on a skyscraper). Endevco VC accelerometers are particularly well suited for measuring low-level accelerations before or after being subjected to a violent shock event (measuring low-level vibrations on a space launch vehicle after surviving the launch event or acceleration of a vehicle before it impacts during a crash safety test).

They are best suited for low frequency vibration from 2 to 200 g's, and from DC (0Hz) to 1000 Hz. The lowest g range units can also be used to measure tilt angle.

Limitations of Variable Capacitance Accelerometers

VC accelerometers can be quite sensitive to temperature variations. But, the Endevco 7290G is specifically designed to overcome this. The state-of-the-art digital temperature compensation electronics provide for precise compensation over a wide temperature range. The use of gas damping results in very small thermally induced changes in frequency response.

Due to their high sensitivity, VC Accelerometers should be recalibrated more often to confirm that they are still within their operating specifications after heavy use applications. We offer complete services to regularly recalibrate sensors and maintain a high level of precision and accuracy in accordance with ISO17025.

Choose the Best Sensor for Your Test Applications

We have thousands of sensors in our online shop in stock, ready to ship, with a lifetime warranty. To discuss specific applications, please contact us or request a quote.